He has established two crusher units. 1) Mavanal Granites Pvt. Ltd. And 2) Vajra Rock Mining Industries in the past years. This group entered into stone crushing when they were doing the sabarimala road development work in the 90’s. In this road work quality broken stone were required and the material was not available in the market, since the government had started the improvement of sabarimala road work in a big way.

The crushing industry was not capable to cater this big demand in road formation. A large quantity of rock has been blasted and removed from the sabarimala road too. The group firm M/s K. N. Madhusoodanan was left with no other way than finding a solution to complete the prestigious work in time. Then they have designed and got assembled a mobile crusher driven with a leyland engine 16/9 crusher with a rotary screen. Through this, the group was able to complete the work in time and paved their way to crushing industry, thus Mavanal and Vajra Crushers.

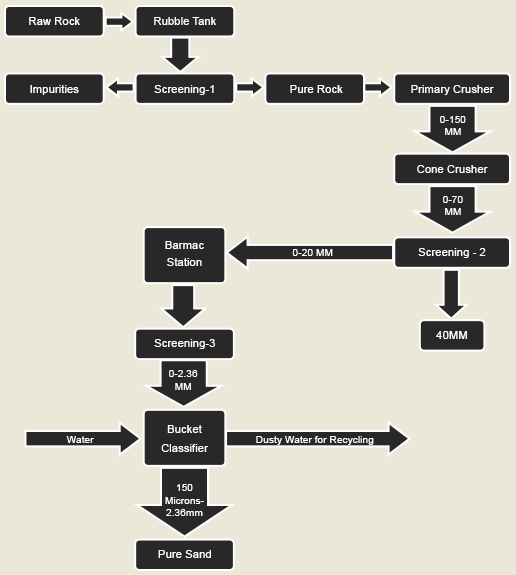

We only use portable quality water for the processing of sand so as to eliminate the chances of chlorides and sulphateson higher level which will affect the durability of structures. We also equipped multi level recycling of water to save water. Full-fledged dust suppression system is operational to protect the environment. Large scale rain water harvesting system with purification arrangements is engaged at an installed capacity of two million liters. Rain water is used to protest the environment by keeping the ground water table intact.

In western countries rock sand is beeing used for years for making concrete and mortar etc. In north India also rock sand is extensively used for all infrastructural projects. But in Kerala river sand was abundantly available. Now the scenario have been changed and river sand is not at all available and even if it is available it is contaminated. The only solution for fine aggregates is to rely on rock sands. Mavanal sand is the pioneer in this field.

Mavanal sand is conforming to the IS standards IS 383-1970 for fine aggregates for concreting, IS 2110-1980 for sand using in masonry work and IS 1542-1992 for plastering puposes. Stringent quality control by experienced engineers is assured in every process which resulted in Mavanal sand’s strict adhesion to Indian standards for durable construction. Our state of the art barmac station is capable of making cubical shaped particles than oval or elongated or flakey particles. The cubical shape of the sand particle gives better packing, better bond and it can reduce the cement consumption also.

| Copyright © 20013-2014 Mavanal | Designed by : Calmove Technologies |